A NASA-funded research team has announced a breakthrough in hypersonic flow technology that could allow operators to control airflow at the speed of light during a deadly “shock train.”

Shock train is a condition that typically precedes engine failure in scramjet engines, and now, for the first time, researchers from the University of Virginia School of Engineering and Applied Science have demonstrated the ability to monitor airflow inside a supersonic combustion jet engine using optical sensors instead of pressure sensors.

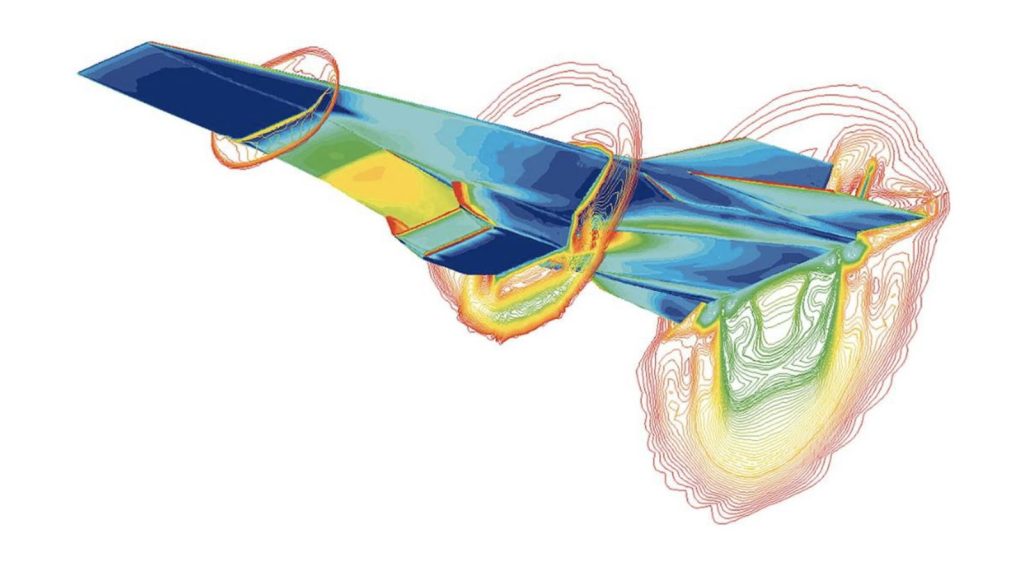

This unprecedented level of sensing and control gives engineers of the scramjet propulsion engines used in hypersonic prototypes an entirely new way to maintain engine performance operating at speeds greater than Mach 5, or five times the speed of sound, when the shock train is observed. Aircraft operating above this threshold are called “hypersonic.”

“If an aircraft is traveling at hypersonic speeds, above Mach 5, it would be logical to think that it would be preferable to embed sensors that operate closer to the speed of light than the speed of sound,” said Professor Christopher Goin, director of the University of Virginia’s Institute for Aeronautics and Astronautics, where the research was conducted.

Shock wave detection essential for hypersonic flight

In press release In announcing their breakthrough in airflow sensing and control, the team points out that NASA’s experimental X-43, or “Hyper-X,” aircraft achieved hypersonic flight 20 years ago. The final version of that aircraft, the X-43A, reached Mach 10 in 2004, the fastest speed reached by an air-breathing aircraft before or since.

Unfortunately, this program and its Air Force successor, the X-51 Waverider program, used older technology to monitor and control the delicate airflows in hypersonic engines. Unlike ramjet engines used in aircraft that fly at supersonic speeds, hypersonic-capable scramjet engines must keep the air flowing at supersonic speeds. As a result, monitoring the airflow with a 2004 pressure sensor that operates at the speed of sound by monitoring pressure waves left engineers with little time to react to adverse airflow conditions.

“When you’re sensing at the speed of sound, but the engine processes are moving faster than the speed of sound, there’s very little response time,” Goin explained.

To avoid the dreaded “no-start” condition, where airflow at a scramjet’s intake drops below the supersonic threshold, the UVA team turned to optical sensors that would give engineers much faster data.

“If something happens in a hypersonic engine and you suddenly create a subsonic condition, it becomes unstartable,” Goin explained. “You get a sudden drop in thrust, and at that point it can be difficult to restart the inlet.”

Optical Sensor Discovers New Way to Detect and Prevent Engine Stalls

According to the team’s research Published In the journal Aerospace Science and TechnologyThe research team believed that using optical sensors to monitor the intake airflow might allow engineers to correct an engine’s condition before a misstart actually occurs. Unlike pressure sensors, however, these sensors must look for optical signals that a misstart is imminent, as opposed to the traditional pressure waves that pressure sensors can detect.

To test their idea, the team used one of UVA’s several wind tunnels. Called the UVA Supersonic Combustion Facility, the wind tunnel can simulate the engine conditions of a hypersonic aircraft traveling at Mach 5. And unlike testing on actual aircraft traveling at hypersonic speeds, the wind tunnel can run for very long periods of time. This flexibility allowed the researchers to collect an unprecedented amount of data on the performance of the optical sensor.

“We can run test conditions for hours, allowing us to experiment with new flow sensors and control approaches in a realistic engine geometry,” explained Chloe Dedic, an associate professor at the University of Virginia and co-author of the published study.

After a few hours of test runs, the team found what they hoped for: by sensing the light emitted by the reacting gases inside the scramjet combustor, and the location and spectral content of the flame, the team was indeed able to identify the conditions that led to a misstart. This wave formation, called a “shock train,” emitted a spectral signature across all three parameters that the team’s optical sensors could detect.

In effect, by analyzing the light spectrum, a way has been found to monitor and control conditions within a scramjet, detecting and acting on shock trains before a misstart occurs. And because this occurs in light species, an optical sensor approach to monitoring this category of airflow could help engineers get ahead of one of the most vexing problems in aero-powered hypersonic flight.

“The light emitted from a flame in an engine is due to the relaxation of molecular species that were excited during the combustion process,” explains Elkowitz, one of the doctoral students. “Different molecular species emit light with different energies, and therefore colors, providing new information about the state of the engine that cannot be captured by pressure sensors.”

Research advances effort to build single-stage orbital vehicle

Going forward, UVA researchers will be working on new test configurations with the goal of creating a working prototype optical shock train detector that can be used for real-world flight testing.

“We are excited to have demonstrated the role optical sensors can play in controlling future hypersonic vehicles,” said Max Y. Chern, a doctoral student and lead author of the study. “We continue to test sensor configurations towards a prototype that optimizes package volume and weight for the flight environment.”

In the longer term, researchers say the ability to achieve hypersonic flight brings the world one step closer to the ultimate goal of a single-stage orbiter that can take off and fly into space like a conventional plane.

“Since the 1960s, one of our nation’s aerospace priorities has been to build a single-stage, orbital aircraft that would take off horizontally like a conventional aircraft, fly into space, and land on the ground like a conventional aircraft,” Goin said. “Today, the most advanced aircraft is SpaceX’s Starship, which has two stages and launches and lands vertically. But to optimize safety, convenience and reusability, the aerospace industry wants to build an aircraft more like a 737.”

When thinking about whether such a goal could be achieved in his lifetime, Goin expressed optimism, especially because he believes his team’s work will bring about great progress.

“We believe this is certainly possible,” Goin said. “The commercial space industry has been successful in driving down costs through reuse, but they have not yet achieved aviation-like operations. Our findings build on Hyper-X’s storied history and could potentially provide safer access to space than current rocket-based technologies.”

Christopher Plain is a science fiction and fantasy novelist and lead science writer at The Debrief. Follow and connect with him: X, To find out about his book Plain FictionOr contact us directly by email. [email protected].