credit: Applied Materials Today (2024). Article number: 10.1016/j.apmt.2024.102140

State University of New York Polytechnic Institute (SUNY Poly) President Dr. Winston “Wole” Soboyejo and postdoctoral researcher Dr. Tabili Kwei Asumadu published a paper titled, “Robust Macroscale Superlubricity on Carbon-Coated Metal Surfaces,” which explores an innovative approach to reducing friction on metal surfaces, a significant advancement that could have a major real-world impact.

This study Published In the journal Applied Materials Today.

This study shows that superlubricity (effectively friction What was once thought to be achievable only at the nanoscale can now be sustained at the macroscale for long periods of time under normal atmospheric conditions using sustainably produced carbon coatings made from bio-waste.

These findings are important for several practical reasons. AutomotiveWith over 30% of fuel in passenger vehicles being used to overcome friction, these new coatings can help significantly improve fuel economy. In manufacturing and industrial machinery, they can help reduce wear, leading to significant cost savings and reducing the 1-4% of a country’s GDP spent on friction-related equipment problems. Electronic DevicesMicroscopic scale friction can pose significant challenges that can be mitigated with coatings.

“This research has the potential to impact just about every industry,” said Dr. Asumadu. “From biomedical to the energy sector to almost any manufacturing industry, this approach could help extend the life of machine parts, reduce maintenance and replacement costs, and create a more sustainable industrial future.”

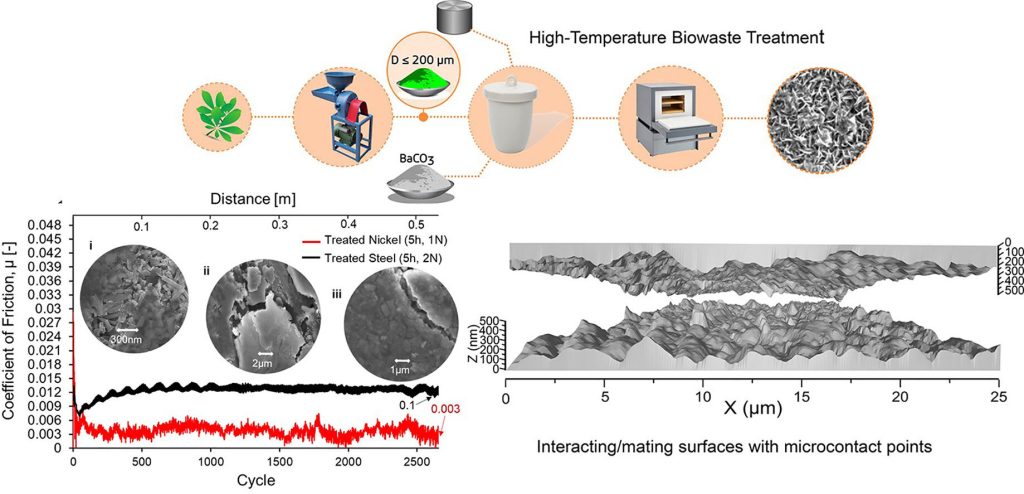

This paper presents experimental and computational results of ultralow friction (near zero) for carbon-coated metal deposits on structural steel, Ti and Ni alloy substrates. Macroscale superlubricity was demonstrated and maintained over several cycles due to the structurally misoriented carbon coating on the metal surface.

Carbon nanocrystals with variations of the graphene footprint were deposited on top of these. Metal Surface Using a novel high-temperature bio-waste treatment process, carbon nanocrystals deform, flatten and fuse at the wear track to form a graphite film, providing an ultra-lubricating friction coefficient of approximately 0.003.

Coating lifetimes of approximately 150,000 cycles were obtained on Ni and steel substrates with reduced wear rates. Experiments were validated with atomistic simulations, providing mechanistic insight into the influence of graphene variants on the observed frictionless conditions.

The underlying mechanism of coatingThe carbon/substrate interactions that contribute to macroscale superlubricity are elucidated. The implications of the present results are discussed for designing robust and low-cost macroscale superlubricious carbon coatings on metal substrates. Biowaste is Carbon source Within Circular Economy Reduce global carbon footprint by using recycled materials.

The paper was published by a group of eight materials scientists collaborating in Africa and the northeastern US, including Mobin Vandadi, Desmond Edem Primus Clennam, Kwadwo Mensah Darkwa, Emmanuel Gikunu, Samuel Kwofi and Nima Rabar.

“My colleagues and I are extremely proud of this research, especially the environmental and economic impact it may have,” said Dr. Soboyejo. “We look forward to seeing breakthroughs in friction management technology as researchers put these approaches to practical use.”

For more information:

Tabiri Kwayie Asumadu et al. “Robust Macroscale Superlubricity on Carbon-Coated Metal Surfaces” Applied Materials Today (2024). Article number: 10.1016/j.apmt.2024.102140

Courtesy of Polytechnic Institute, SUNY

Quote: Superlubricity research shows frictionless state can be achieved on the macroscale (July 15, 2024) Retrieved July 16, 2024 from https://phys.org/news/2024-07-superlubricity-frictionless-state-macroscale.html

This document is subject to copyright. It may not be reproduced without written permission, except for fair dealing for the purposes of personal study or research. The content is provided for informational purposes only.